Oil re-refining

Overview

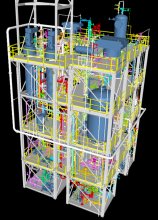

USED OIL REFINERY PLANT

As EPC contractor, we undertake all the activities from design, procurement, construction, commissioning to handover of the complete re-refinery to our esteemed customers.

Every re-refinery customer has custom requirement. We implement the latest 3-D modeling tools to design every re-refinery. This enables us to complete the entire plant building procedure in the most accurate and timely manner. Our tested and proven Re-Refining process technology provides maximum yield from the used waste lube oil, Engine oil, lubricant (Black Oil) in an environmentally friendly manner. The process plants that we build for you are pre-assembled, pre-insulated, pre-wired and ready for installation and commissioning.

Used Oil Re-refining plant

Bpsps has developed state-of-the-art, proprietary technology known as Bpsps-Wiped-Film-Evaporation (TWFE) to produce higher process efficiencies by minimizing bottom components and maximizing reclamation / regeneration of the useful ingredients from used lube oil. TWFE technology can extend the yields of saleable products up to 95% – 97% of the used oil feed. The high yield in the TWFE process is due to innovative equipment design and design optimizations of the process. TWFE process is acid-free, solvent-free and sludge-free. The bottom residue generated in the process can also be sold as a finished product, such as asphalt/bitumen modifier. TWFE adapts very well to feedstock variability such as used lube oils containing a high amount of water, low boilers, additives, transformer oils, turbine oils, hydraulic and synthetic oils.

Complete Automation, PLC Control and SCADA based process enables a safe and smooth plant operation with minimum manpower, in an environment-friendly manner.

With our Re-Refining experience of over a decade and continuous process improvements, we have a proven and established process, as described below:

- Stage 1: De-Hydration and De-Gas Oil (Skid mounted package unit)

- Stage 2-A: TWFE #1 to Process SN150 (Skid mounted package unit)

- Stage 2-B: TWFE #2 to Process SN300 (Skid mounted package unit)

- Stage 2-C: TWFE #3 to Process SN400/500 (Skid mounted package unit)

- Stage 3-A: Hydrogenation (for API Group II Skid mounted package unit)

- Stage 3-B: Media polishing (for API Group I Skid mounted package unit)

- Stage 4: Pollution control gaseous emissions (Skid mounted package unit)

- Stage 5: Effluent water treatment for water from the dehydration step

- Stage 6: Packaging or bulk dispatch

The Process Output

77% of Base Oil ( SN 80, SN 150, 300, 400-500)

4% Diesel, Naphtha & Light Oil

14% of residue (Asphalt)

4% water

1% process losses

-

- Wiped Film Evaporator (WFE) Technology

-

Our WFE technology distills used oil, removing heavy carbons with metals in the residue stream, to produce a lube distill.

The WFE design allows for the distillation of used oil at high vacuum levels to reduce the boiling point to prevent thermal cracking of the oil and allowing manageable operating temperatures that can be serviced by typical plant hot oil heating systems.

Used oil distillation is a fouling application; however, the wiping action of the WFE blades continuously cleans the heat transfer surface of the WFE.

-

- Pilot Test Facility

-

At our test facility in Rochester, NY we perform evaporative pilot studies to determine the optimum operating conditions and performance capabilities of our WFE and column technologies. Oil re-refining is a common test for us, so by testing your used oil collections material we can confirm design and propose a solution for your processing needs.

At our test facility in Rochester, NY we perform evaporative pilot studies to determine the optimum operating conditions and performance capabilities of our WFE and column technologies. Oil re-refining is a common test for us, so by testing your used oil collections material we can confirm design and propose a solution for your processing needs.

-

- Engineered Systems

-

Our engineering resources include all disciplines (civil, mechanical, chemical and electrical) enabling us to design turn-key systems.

Our chemical process engineers are experienced in all chemical unit operations, such as the evaporation, mixing, heat transfer, fluid mechanics, and vacuum technologies required for oil re-refining. Our project engineers use their experience, equipment and instruments to complete the detailed design of the system, whilst our designers use CAD to create an efficient plant layout.

For a smooth, seamless project execution and delivery, our project managers oversee all stages, keeping them on time and in budget and to finish off the project, our process engineers will work with you to commission the system.

-

- Complete Oil Re-Refining System

-

We design complete oil re-refining systems.

With our WFE technology at the core of the system, we distill the oil to produce the lube distillate. We add all the upfront systems for pretreatment of the oil, water removal, Naptha removal and gas-oil separation. Finally, a very complex multi-stage vacuum system is added to create the high vacuum required in the WFE for the oil distillation and the other moderate vacuum levels needed in the various stages of lights removal.